Medical devices

search

news

The PDF with the short report with pictures from the therapy of a diabetic foot can be viewed or downloaded here.

The pictures from the treatment of unhealing wounds an be found here:

http://www.onkocet.eu/en/produkty-detail/220/1/

The pictures from the treatment of unhealing wounds an be found here:

http://www.onkocet.eu/en/produkty-detail/293/1/

ONKOCET Ltd. has exhibited the devices from its portfolio on the MEDTEC UK exhibition in Birmingham, April 2011 through our partner Medical & Partners.

The ONKOCET company has successfully reached the certification of yet another medical device, Infrared Camera SVIT. The Certificate can be found here. The videos from the device operation can be found here.

The ONKOCET company has successfully reached the certification of yet another medical device, Infrared Camera SVIT. The Certificate can be found here. The videos from the device operation can be found here. Our device, the non-invasive blood analyzer AMP has won the Golden Incheba prize at a medical exhibition SLOVMEDICA - NON-HANDICAP 2010. A big thank you goes to the organizers of the exhibition for acknowledging the quality of our device and to the exhibitor, the Medical & Partners company, for introduction of the AMP device to the medical public again.

Our device, the non-invasive blood analyzer AMP has won the Golden Incheba prize at a medical exhibition SLOVMEDICA - NON-HANDICAP 2010. A big thank you goes to the organizers of the exhibition for acknowledging the quality of our device and to the exhibitor, the Medical & Partners company, for introduction of the AMP device to the medical public again.We are pleased to inform our business partners, that our company has succesfully finished the certification process of Concor Soft Contact Lenses.

You can find the certificate here.

You can find the certificate here.More information on Concor Soft Contact Lenses go to section Medical preparations/Concor soft contact lenses, or follow this link.

Our company has finished the certification process for another medical device, computerized spirometer MAS-1K with oximeter. You can find the device certificate here.

Our company has finished the certification process for another medical device, computerized spirometer MAS-1K with oximeter. You can find the device certificate here..jpg) Since May 2010 there is a new version of AMP device available.

Since May 2010 there is a new version of AMP device available.Follow this link if you want to see the pictures and specifications of the device.

http://www.onkocet.eu/en/produkty-detail/293/1/

Dear partners,

Dear partners, In October 2009 we have received CE certificate for another device from our portfolio, NO therapeutical device PLASON. You can find more information about this revolutionary device, used for healing of unhealing wounds, diabetic foot, or for cosmetical purposes, at our webpage, section "Medical devices" -> PLASON-NO Therapy.

.gif)

Best regards

Team of ONKOCET Ltd. company

Control System

Control System

1. Brief Introduction

1.1 Overview

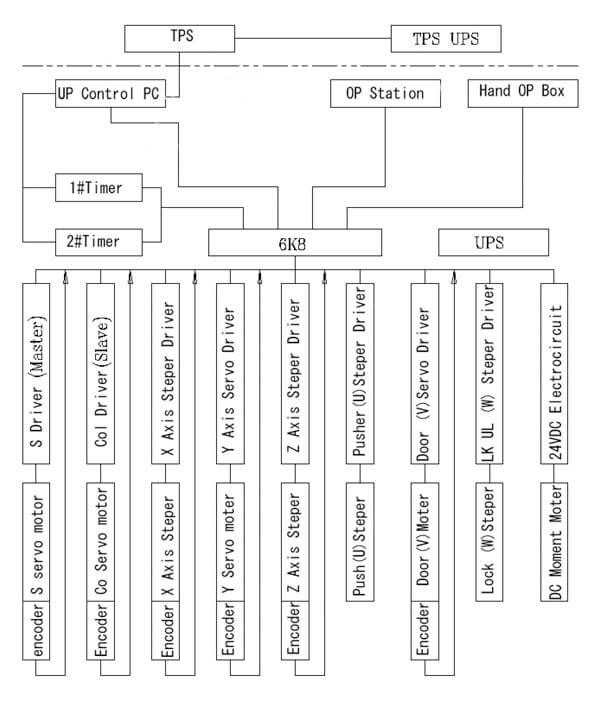

Electric Control System is composed of upper control computer, operation box, manual remote control box, timers, UPS, motion controller, drivers, motors, increment encoders, logic circuits limit switches, monitoring system, and intercommunication system. The main functions of the Electric Control System is: to control X, Y, and Z axis movement and localization of the treatment bed; to position and rotate the source carrier and the collimator carrier; to open, close, load and unload the cobalt sources; to import treatment data, to display the state of the equipment in the process of treatment, and to monitor the equipment and the patients. In order to ensure the security of the patients and the operators, the system is also equipped with safety interlocking and audible-visual alarm.

The operation of the treatment is accomplished on the console on which there is upper control computer, operation box, intercommunication system and monitoring system. The operation section of the console is composed of operation box, and manual remote control box. Using the upper control computer to monitor and control the running state of the equipment; operating the buttons on the operation box to control the operation, pause and emergency stop of SGS; using the indicator lights on the operation box to be aware of the running status of the system. In addition, the buzzing alarm on the operation box can be activated to remind the operators when there is something wrong with the system. The manual remote control box is used when the axis of SGS need respective movement. The monitoring system and the intercommunication system are installed in the treatment room and the control room. The operators can observe the whole treatment process and communicate with the patients through the monitor and microphone of the console.

The electrical source is supplied by Electric Supply and online UPS. When there is something wrong with the Electric Supply, UPS will be able to make the equipment run properly for more than 30 minutes to make sure that the treatment will not be broken off when power is suddenly failed.

The actuators of source carrier and collimator carrier include the drivers, servo motors, incremental encoders, etc. The position detection and localization among source carrier and collimator carrier is accomplished by the incremental encoders. The opening and closing of radiation source is displayed by the status indicator lamp. In addition, the rotating speed and rotating range which is used by the upper control computer to control the 6K8 motion controller is determined by the treatment planning. During the treatment, the maximum rotating speed of source carrier and collimator carrier is 1rpm.

The x movement and z movement of the treatment bed is achieved by the decelerated motion device which is driven by the stepping motor. The y movement is achieved by the decelerated motion device which is driven by servo motor. The position of all the movements is fed back to the 6K8 controller through the encoders, which can ensure the positioning accuracy of the treatment bed. Moreover, the three axes on the treatment bed have zero switch and positive-negative motion limit switches which can ensure the safety operation of the treatment bed and the determination of the axis’ zero position. The barrier of the source storage is driven by servo motor, while the handspike and the source box lock is driven by stepping motor. The position verification is achieved by proximity switch.

The diagram of Electric Control System is as following:

The control of radiation dose of SGS-I is composed of two independent timers. These two timers use redundancy association and can stop the radiation process independently. When SGS is started to radiate, one timer is timing ascendingly and the other is timing descendingly. Timers will be displayed in the Remaining Time and Elapsed Time on the control board. The value of timers is initialized by the upper control computer. When one of the timers goes out of order (the count value of the two timers has more than five seconds difference or one of the timers powers down), the treatment will be terminated with alarm tone and the failure will be shown on the upper control computer. When the radiation is stopped accidentally, the value of the current timers will be saved individually on the timers and the upper control computer for later examination.