Medical devices

search

news

The PDF with the short report with pictures from the therapy of a diabetic foot can be viewed or downloaded here.

The pictures from the treatment of unhealing wounds an be found here:

http://www.onkocet.eu/en/produkty-detail/220/1/

The pictures from the treatment of unhealing wounds an be found here:

http://www.onkocet.eu/en/produkty-detail/293/1/

ONKOCET Ltd. has exhibited the devices from its portfolio on the MEDTEC UK exhibition in Birmingham, April 2011 through our partner Medical & Partners.

The ONKOCET company has successfully reached the certification of yet another medical device, Infrared Camera SVIT. The Certificate can be found here. The videos from the device operation can be found here.

The ONKOCET company has successfully reached the certification of yet another medical device, Infrared Camera SVIT. The Certificate can be found here. The videos from the device operation can be found here. Our device, the non-invasive blood analyzer AMP has won the Golden Incheba prize at a medical exhibition SLOVMEDICA - NON-HANDICAP 2010. A big thank you goes to the organizers of the exhibition for acknowledging the quality of our device and to the exhibitor, the Medical & Partners company, for introduction of the AMP device to the medical public again.

Our device, the non-invasive blood analyzer AMP has won the Golden Incheba prize at a medical exhibition SLOVMEDICA - NON-HANDICAP 2010. A big thank you goes to the organizers of the exhibition for acknowledging the quality of our device and to the exhibitor, the Medical & Partners company, for introduction of the AMP device to the medical public again.We are pleased to inform our business partners, that our company has succesfully finished the certification process of Concor Soft Contact Lenses.

You can find the certificate here.

You can find the certificate here.More information on Concor Soft Contact Lenses go to section Medical preparations/Concor soft contact lenses, or follow this link.

Our company has finished the certification process for another medical device, computerized spirometer MAS-1K with oximeter. You can find the device certificate here.

Our company has finished the certification process for another medical device, computerized spirometer MAS-1K with oximeter. You can find the device certificate here..jpg) Since May 2010 there is a new version of AMP device available.

Since May 2010 there is a new version of AMP device available.Follow this link if you want to see the pictures and specifications of the device.

http://www.onkocet.eu/en/produkty-detail/293/1/

Dear partners,

Dear partners, In October 2009 we have received CE certificate for another device from our portfolio, NO therapeutical device PLASON. You can find more information about this revolutionary device, used for healing of unhealing wounds, diabetic foot, or for cosmetical purposes, at our webpage, section "Medical devices" -> PLASON-NO Therapy.

.gif)

Best regards

Team of ONKOCET Ltd. company

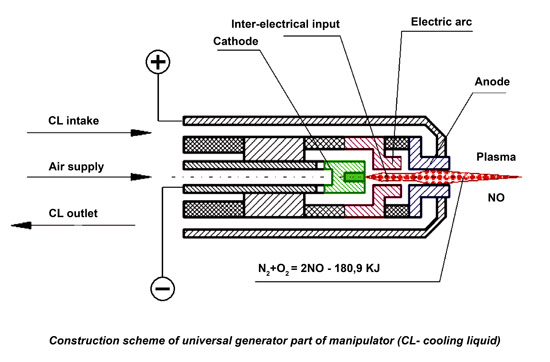

Generation of NO-containing plasma

Air- plasma manipulator - basic element of the PLASON® device

Therapeutic action using the PLASON® device is achieved by supply of the gas flows of a different temperature (from 4000°C to the ambient temperature), but with the constant content of the nitric oxide (NO) in the flow, to the biological tissues . This is reached by forced pumping of atmospheric air through the operating unit of the device - manipulator.

From a technical point of view all manipulators of the PLASON® device are generators of the direct current plasma, made according to linear three-electrode scheme. Figure depicts the design concept of the standardized generator part of the manipulator. The electric arc, geometrically stabilized by the channel of insert interelectrode, burns with the connection of manipulator to the source of the direct and stabilized current between the cathode and the anode. Atmospheric air is sucked into the manipulator with the built-in microcompressor, it penetrates the electric arc, is heated and accelerated, converted to plasma state, and through the opening in the anode it elapses from the generator part of the manipulator. The geometric parameters of the channel of generator part, the energy characteristics of electric power supply and cooling of electric arc are selected in such way that the temperature of gas in the arc is optimum for nitric oxide forming.

The compositional analysis of the thermodynamical equilibrium air plasma shows that at a temperature lower than 2000°C the concentration of NO in the gas does not exceed 1%. With an increase in the temperature it rapidly increases and reaches its maximum (~5%) at a temperature of 3500-4000°C. Precisely this temperature range is optimum for the generation of the nitric oxide. The gamma of the chain and branching, reversible plasma-chemical reactions, which lead to formation NO, can be expressed by the following chemical formula:

N2 + O2 <-> 2NO - 180,9 kJ

In connection with the fact that the stability of the nitric oxide molecule at high temperatures is adequate to the time of its synthesis, it is necessary to accomplish rapid cooling of reaction mixture - hardening.

In the case of manipulator - coagulator and manipulator - destructor the heated air- plasma flow (APF) elapses directly into the surrounding space in the form of vividly luminous torch. Hardening of the nitric oxide occurs with braking of the escaping flow in surrounding cold air. Coagulator and destructor differ only in the diameter of the output anodic channel - 1,2 mm and 0,7 mm respectively. By this the difference in the discharge velocity of air- plasma jet - to 200 m/s for the coagulator and to 600 m/s for destructor is reached. The APF temperature with the expiration in the surrounding space in the shear of outlet reaches 4000°C, which is sufficient for obtaining of the surgical effects (coagulation and destruction).

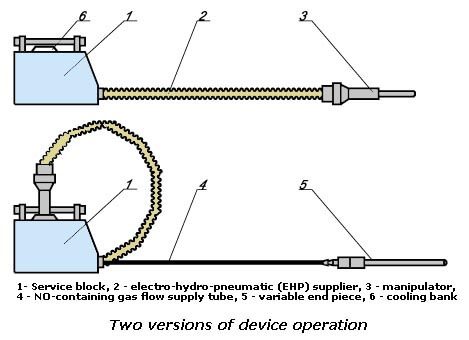

In a number of cases - with the small surgical intervention, in the absence of intensive hemorrhages and for conducting the sessions of NO-therapy there is no need for giving such a hot flow to the cloths. The temperature of gas flow must be reduced, but not to decrease the nitric oxide content in it. By PLASON® device this goal is achieved through the additional cooling of the flow, which escapes from the generator unit, what allows, from one side, to reduce the temperature of flow up to the ambient temperature, and from the other side - to " freeze" in it the molecules of the nitric oxide, originated in the electric arc of generator unit. PLASON® device uses two methods of additional cooling. The first - this is the scheme of the additional cooler connected to the generator part, the second - scheme with built-in labyrinth type powerful additional cooler in the service unit of the device. According to the first scheme, air- plasma flow from the generator part of the manipulator is sent to the channel of additional cooling, from which it elapses into the surrounding space. By changing of the channel of additional cooling length, it is possible to reach practically any reduction in the temperature of flow at the output from the manipulator. The manipulator designed according to the scheme of the additional connected cooler received name stimulator or stimulator - coagulator. It is equally appropriate both for the stoppage of diffuse hemorrhages and for conducting of the NO- therapy sessions.

For obtaining of the NO-containing gas flow (NO-CGF) with room temperature, the scheme of labyrinth type additional built-in cooler is realized. As shown in figure, any manipulator can be established into the special nest of cooler, located in the upper part of the apparatus. As a result of cooling in the built-in cooler the temperature of the flow, generated by manipulator, is reduced to the room temperature. The supply of the cooled NO- containing gas flow (NO-CGF) to the object is accomplished by special flexible supply with interchangeable tips.