Medical devices

search

news

The PDF with the short report with pictures from the therapy of a diabetic foot can be viewed or downloaded here.

The pictures from the treatment of unhealing wounds an be found here:

http://www.onkocet.eu/en/produkty-detail/220/1/

The pictures from the treatment of unhealing wounds an be found here:

http://www.onkocet.eu/en/produkty-detail/293/1/

ONKOCET Ltd. has exhibited the devices from its portfolio on the MEDTEC UK exhibition in Birmingham, April 2011 through our partner Medical & Partners.

The ONKOCET company has successfully reached the certification of yet another medical device, Infrared Camera SVIT. The Certificate can be found here. The videos from the device operation can be found here.

The ONKOCET company has successfully reached the certification of yet another medical device, Infrared Camera SVIT. The Certificate can be found here. The videos from the device operation can be found here. Our device, the non-invasive blood analyzer AMP has won the Golden Incheba prize at a medical exhibition SLOVMEDICA - NON-HANDICAP 2010. A big thank you goes to the organizers of the exhibition for acknowledging the quality of our device and to the exhibitor, the Medical & Partners company, for introduction of the AMP device to the medical public again.

Our device, the non-invasive blood analyzer AMP has won the Golden Incheba prize at a medical exhibition SLOVMEDICA - NON-HANDICAP 2010. A big thank you goes to the organizers of the exhibition for acknowledging the quality of our device and to the exhibitor, the Medical & Partners company, for introduction of the AMP device to the medical public again.We are pleased to inform our business partners, that our company has succesfully finished the certification process of Concor Soft Contact Lenses.

You can find the certificate here.

You can find the certificate here.More information on Concor Soft Contact Lenses go to section Medical preparations/Concor soft contact lenses, or follow this link.

Our company has finished the certification process for another medical device, computerized spirometer MAS-1K with oximeter. You can find the device certificate here.

Our company has finished the certification process for another medical device, computerized spirometer MAS-1K with oximeter. You can find the device certificate here..jpg) Since May 2010 there is a new version of AMP device available.

Since May 2010 there is a new version of AMP device available.Follow this link if you want to see the pictures and specifications of the device.

http://www.onkocet.eu/en/produkty-detail/293/1/

Dear partners,

Dear partners, In October 2009 we have received CE certificate for another device from our portfolio, NO therapeutical device PLASON. You can find more information about this revolutionary device, used for healing of unhealing wounds, diabetic foot, or for cosmetical purposes, at our webpage, section "Medical devices" -> PLASON-NO Therapy.

.gif)

Best regards

Team of ONKOCET Ltd. company

Identification System

Identification System

Freza Ltd. company produces burs with a wide variety of geometrical forms, sizes, and kinds of cutting surfaces ensuring any type of dental operations. There are burs of the following forms:

• cylindrical,

• cylindrical rounded,

• cylindrical pointed,

• needle-shaped

• conical

• tapered rounded

• tapered pointed

• tapered fine

• inverted conical rounded

• inverted conical

• parabolic

• flame

• elliptical

• pear-shaped

• round

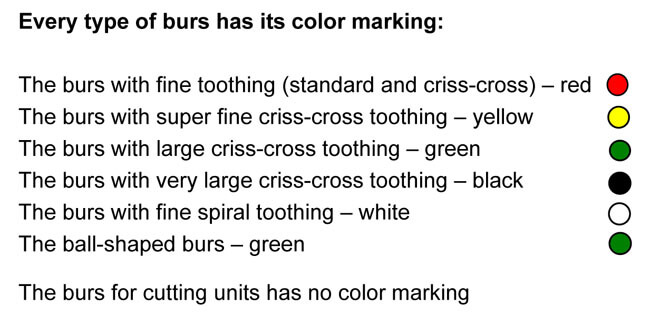

The Company produces burs with the following forms of the cutting edge:

• thin symmetrical spiral cross-cut teeth

• normal right-side teeth

• normal right-side teeth with left-side spiral cross-cut thread

• normal symmetrical spiral cross-cut teeth

• very large symmetrical spiral cross-cut teeth

In total there are more than 80 items in “Freza” Ltd. company portfolio.

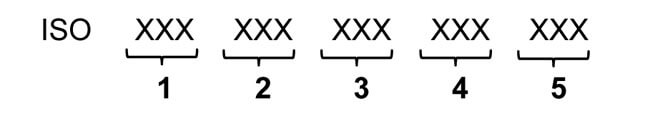

Every bur has a digital code - the ISO number. It consists of 15 figures (according to GOST R 50350.1-92 Dental rotary instruments. Number coding system. Part 1. General characteristics (ISO 6360-1-85) and GOST R 50350.2-92 (ISO 6360-2-85) Dental rotary instruments. Number coding system. Part 2. Shape and specific characteristics).

1. The first 3 figures describe the material of the working part and covering.

500 = tungsten carbide. We use only one kind of hard alloy appropriate to the application groups M10, K10 in accordance with ISO 513-2004 – tungsten carbide.

So, 500 are the first figures in the ISO number for all our burs without covering or with cover-ing of special type.

2. The second triple describes the shank (4th and 5th figures) and the overall length (6th figure).

104 = we use the shank of II type (according to GOST 26634-91 (ISO 1797-85) for fix in the straight handpieces. It is marked as 10. The overall length is standard for all our burs. It has the digital code 4.

So, 104 is the second triple of figures in the ISO number for all our burs.

3. The third triple of figures describes the shape of the working part of the bur.

001 = round (spherical)

112 = cylindrical

123 = cylindrical

116 = cylindrical

137 = cylindrical rounded

141 = cylindrical rounded

143 = cylindrical rounded

185 = needle-shaped

186 = needle-shaped

198 = tapered pointed

199 = tapered fine

200 = tapered rounded

201 = tapered rounded

225 = inverted conical

237 = inverted conical rounded/ peer-shaped

243 = flame standard

257 = flame

274 = parabolic

277 = elliptical

289 = cylindrical pointed

291 = cylindrical pointed

468 = tapered triangular

4. The forth triple of figures describes the type of cutting:

110 = cross cut super fine

140 = cross cut fine

175 = plain cut standard

176 = spiral fine

190 = cross cut large

220 = cross cut coarse (very large symmetrical spiral cross-cut teeth)

135 = left-hand spiral cut fine

103 = left-hand spiral superfine

133 = right-hand spiral fine

336 = right-handed spiral large

5. The last three figures (the fifth triple) describe the nominal size – the largest head diameter of working part in 1/10 mm

010 = Size 1.0 mm

012 = Size 1.2 mm

014 = Size 1.4 mm

016 = Size 1.6 mm

018 = Size 1.8 mm

021 = Size 2.1 mm

023 = Size 2.3 mm

040 = Size 4.0 mm

050 = Size 5.0 mm

060 = Size 6.0 mm

2.2.1 Digital code of every bur obeys GOST R 50350.1-92 Dental rotary instruments. Number coding system. Part 1. General characteristics. (ISO 6360-1-85 “Dental rotary instruments. Number coding system. Part 1. General characteristics.”) and GOST R 50350.2-92 Dental rotary instruments. Number coding system. Part 2. Shape and specific characteristics. (ISO 6360-2-85 “Dental rotary instruments. Number coding system. Part 2. Shape and specific characteristics.”).

2.2.2 Burs with standard fine toothing (see Pictures 1-7) are used for finishing operations and slight removal of gold, other metal and acrylic plastic materials.