Medical devices

search

news

The PDF with the short report with pictures from the therapy of a diabetic foot can be viewed or downloaded here.

The pictures from the treatment of unhealing wounds an be found here:

http://www.onkocet.eu/en/produkty-detail/220/1/

The pictures from the treatment of unhealing wounds an be found here:

http://www.onkocet.eu/en/produkty-detail/293/1/

ONKOCET Ltd. has exhibited the devices from its portfolio on the MEDTEC UK exhibition in Birmingham, April 2011 through our partner Medical & Partners.

The ONKOCET company has successfully reached the certification of yet another medical device, Infrared Camera SVIT. The Certificate can be found here. The videos from the device operation can be found here.

The ONKOCET company has successfully reached the certification of yet another medical device, Infrared Camera SVIT. The Certificate can be found here. The videos from the device operation can be found here. Our device, the non-invasive blood analyzer AMP has won the Golden Incheba prize at a medical exhibition SLOVMEDICA - NON-HANDICAP 2010. A big thank you goes to the organizers of the exhibition for acknowledging the quality of our device and to the exhibitor, the Medical & Partners company, for introduction of the AMP device to the medical public again.

Our device, the non-invasive blood analyzer AMP has won the Golden Incheba prize at a medical exhibition SLOVMEDICA - NON-HANDICAP 2010. A big thank you goes to the organizers of the exhibition for acknowledging the quality of our device and to the exhibitor, the Medical & Partners company, for introduction of the AMP device to the medical public again.We are pleased to inform our business partners, that our company has succesfully finished the certification process of Concor Soft Contact Lenses.

You can find the certificate here.

You can find the certificate here.More information on Concor Soft Contact Lenses go to section Medical preparations/Concor soft contact lenses, or follow this link.

Our company has finished the certification process for another medical device, computerized spirometer MAS-1K with oximeter. You can find the device certificate here.

Our company has finished the certification process for another medical device, computerized spirometer MAS-1K with oximeter. You can find the device certificate here..jpg) Since May 2010 there is a new version of AMP device available.

Since May 2010 there is a new version of AMP device available.Follow this link if you want to see the pictures and specifications of the device.

http://www.onkocet.eu/en/produkty-detail/293/1/

Dear partners,

Dear partners, In October 2009 we have received CE certificate for another device from our portfolio, NO therapeutical device PLASON. You can find more information about this revolutionary device, used for healing of unhealing wounds, diabetic foot, or for cosmetical purposes, at our webpage, section "Medical devices" -> PLASON-NO Therapy.

.gif)

Best regards

Team of ONKOCET Ltd. company

Coagulation

Coagulation of the wound surfaces

Coagulation is achieved by bringing the high-temperature air-plasma flow (HPF) directly to the wound surface. The temperature of flow in the region of contact must be not less than 2000°C, therefore, distance from the outlet of manipulator-coagulator to the region of action must be not more than 25 mm.

Coagulation is achieved by bringing the high-temperature air-plasma flow (HPF) directly to the wound surface. The temperature of flow in the region of contact must be not less than 2000°C, therefore, distance from the outlet of manipulator-coagulator to the region of action must be not more than 25 mm.

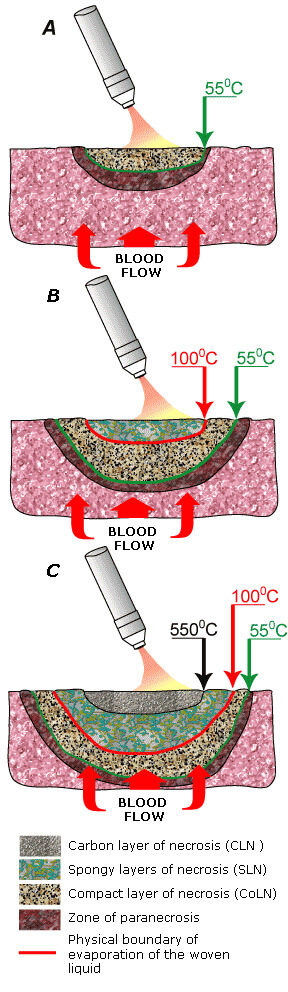

At the first moment of time (Fig. a) during bringing of energy HPF with the temperature more than 2000°C to the biological tissue its heating to the boiling point of woven liquid occurs.

Compact layer of necrosis (CLN), which consists of the degradation products of protein connections is formed, partially damaged and nonviable, but preserved their structure cells (55°C), and the zone of paranecrosis - zone of the partially reversible changes in the cells. Subsequently the zone of paranecrosis becomes the source of regeneration.

Further increase in the time of action (Fig. b) leads to strengthening of the process of boiling and evaporating the woven liquid. The spongy layer of necrosis (SLN) is formed - the porous, elastic and airtight structure, which consists of the dehydrated protein and fatty connections.

Clearly expressed physical boundary of the evaporation of liquid appears in the cloth, which divides the spongy (SLN) and compact (CLN) layers of necrosis (100°C). Upper temperature boundary of the spongy layer of necrosis coincides with the temperature of the beginning of the thermal decomposition of protein and fatty compounds into the simplest chemical elements (550°C, Fig. c).

Above [SLN] is formed the carbonized (carbon) layer of necrosis (CaLN), which is the burnt and charred cloth. Qualitative hem-aero-lymph-cholestasis is determined by the positive dynamics of shaping of the compact and spongy layers of necrosis or by the low rate of shaping of the carbon layer of necrosis.

The thermo-physical and geometric parameters of the plasma flow of coagulator are optimized so that reliable hem-aero-lymph-cholestasis is reached on any biological cloths and at any speeds of counter blood flow. The significant (about 200 m/s) discharge velocity of hot gas from the outlet of coagulator creates condition on the surface of the coagulated section of the cloth, with which coagulation layers are formed directly from cloth itself, but not of the counter-flows of the liquid, for example, of the blood or lymph entering.

A change in the time of action and distance from the outlet of coagulator to the region of coagulation is the universal method of the dosage of the energy necessary for the coagulation. For obtaining the reliable coagulation the distance from the outlet of manipulator lies within the limits from 2 to 25 mm.

.jpg)